They have got my project on time with competition well-organized and very experienced team of professional engineers.

-

-

Mobile: +971 58 677 7772

Email: sales@ykmgroup.com

Mobile: +971 58 677 7772

Email: sales@ykmgroup.com

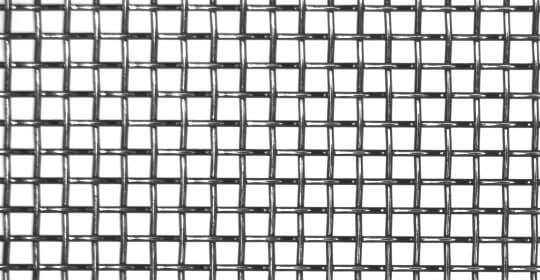

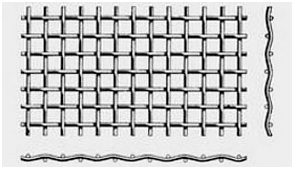

In a plain weave pattern, each weft wire passes alternately over and under thew arp wire and vice versa. It is the most widely available pattern and typically incorporates wire of the same diameter in both directions. Available as standard specifications from 11mm to 50 micron and also from bespoke manufacture, plain weaves are considered to be the most stable mesh form and are used in many applications throughout manufacturing industry.

| Square wire Mesh | |||||

| Mesh Per Linear Inch | Wire diameter inches | Wire diameter mm | Width of opening inches | Width of opening mm | Open Area % |

|---|---|---|---|---|---|

| 1x1 | 0.156 | 4 | 0.84 | 21.4 | 71 |

| 2x2 | 0.118 | 2.5 | 0.38 | 10.2 | 64 |

| 3x3 | 0.079 | 2 | 0.25 | 6.4 | 58 |

| 4x4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 |

| 4x4 | 0.047 | 1.19 | 0.203 | 5.16 | 65.9 |

| 5x5 | 0.055 | 1.4 | 0.14 | 3.68 | 52 |

| 6x6 | 0.047 | 1.2 | 0.12 | 3.03 | 51 |

| 8x8 | 0.043 | 1.1 | 0.08 | 2.08 | 42 |

| 10x10 | 0.039 | 1 | 0.06 | 1.54 | 36 |

| 10x10 | 0.02 | 0.51 | 0.08 | 2.03 | 64 |

| 12x12 | 0.023 | 0.584 | 0.06 | 1.52 | 51.8 |

| 12x12 | 0.02 | 0.508 | 0.063 | 1.6 | 57.2 |

| 14x14 | 0.023 | 0.584 | 0.048 | 1.22 | 45.2 |

| 14x14 | 0.02 | 0.508 | 0.051 | 1.3 | 51 |

| 16x16 | 0.018 | 0.457 | 0.0445 | 1.13 | 50.7 |

| 18x18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48.3 |

| 20x20 | 0.02 | 0.508 | 0.03 | 0.76 | 36 |

| 20x20 | 0.016 | 0.406 | 0.034 | 0.86 | 46.2 |

| 24x24 | 0.014 | 0.356 | 0.0277 | 0.7 | 44.2 |

| 30x30 | 0.013 | 0.33 | 0.203 | 52 | 37.1 |

| 30x30 | 0.012 | 0.305 | 0.0213 | 0.54 | 40.8 |

| 30x30 | 0.009 | 0.229 | 0.0243 | 0.62 | 53.1 |

| 35x35 | 0.011 | 0.279 | 0.0176 | 0.45 | 37.9 |

| 40x40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 |

| 50x50 | 0.009 | 0.229 | 0.011 | 0.28 | 30.3 |

| 50x50 | 0.008 | 0.203 | 0.012 | 0.31 | 36 |

| 60x60 | 0.0075 | 0.191 | 0.0092 | 0.23 | 30.5 |

| 60x60 | 0.007 | 0.178 | 0.0097 | 0.25 | 3390 |

| 70x70 | 0.0065 | 0.165 | 0.0078 | 0.2 | 29.8 |

| 80x80 | 0.0065 | 0.165 | 0.006 | 0.15 | 23 |

| 80x80 | 0.0055 | 0.14 | 0.007 | 0.18 | 31.4 |

| 90x90 | 0.005 | 0.127 | 0.0061 | 0.16 | 30.1 |

| 100x100 | 0.0045 | 0.114 | 0.0055 | 0.14 | 30.3 |

| 100x100 | 0.004 | 0.102 | 0.006 | 0.15 | 36 |

| 100x100 | 0.0035 | 0.089 | 0.0065 | 0.17 | 42.3 |

| 110x110 | 0.004 | 0.1016 | 0.0051 | 0.1295 | 30.7 |

| 120x120 | 0.0037 | 0.094 | 0.0046 | 0.1168 | 30.7 |

| 150x150 | 0.0026 | 0.066 | 0.0041 | 0.1041 | 37.4 |

| 160x160 | 0.0025 | 0.0635 | 0.0038 | 0.0965 | 36.4 |

| 180x180 | 0.0023 | 0.584 | 0.0033 | 0.0838 | 34.7 |

| 200x200 | 0.0021 | 0.0533 | 0.0029 | 0.0737 | 33.6 |

| 250x250 | 0.0016 | 0.0406 | 0.0024 | 0.061 | 36 |

| 270x270 | 0.0016 | 0.0406 | 0.0021 | 0.0533 | 32.2 |

| 300x300 | 0.0015 | 0.381 | 0.0018 | 0.457 | 29.7 |

| 325x325 | 0.0014 | 0.356 | 0.0017 | 0.432 | 30 |

| 400x400 | 0.001 | 0.254 | 0.0015 | 0.037 | 36 |

| 500x500 | 0.001 | 0.0254 | 0.001 | 0.0254 | 25 |

| 635x635 | 0.0008 | 0.0203 | 0.0008 | 0.0203 | 25 |

| Tensile Bolt Bolting Cloth | ||||||

| Meshes Per Linear Inch | Width of Opening Inches | Width of Opening mm | Diameter of Wire Inches | Diameter of Wire mm | Open Area % | Weight 100 Sp.ft |

|---|---|---|---|---|---|---|

| 16x16 | 0.0535 | 1.36 | 0.009 | 0.229 | 73.3 | 8.38 |

| 18x18 | 0.0466 | 1.18 | 0.009 | 0.229 | 70.2 | 9.48 |

| 24x24 | 0.0342 | 0.869 | 0.0075 | 0.191 | 67.2 | 8.75 |

| 28x28 | 0.0282 | 0.716 | 0.0075 | 0.191 | 62.4 | 10.29 |

| 30x30 | 0.0268 | 0.681 | 0.0065 | 0.165 | 64.8 | 8.35 |

| 36x36 | 0.0213 | 0.541 | 0.0065 | 0.165 | 58.7 | 10.09 |

| 40x40 | 0.0185 | 0.47 | 0.0065 | 0.165 | 54.8 | 11.29 |

| 50x50 | 0.0145 | 0.368 | 0.0055 | 0.127 | 52.6 | 10.14 |

| 60x60 | 0.0122 | 0.31 | 0.0045 | 0.114 | 53.3 | 8.13 |

| 70x70 | 0.0106 | 0.269 | 0.0037 | 0.094 | 54.9 | 6.4 |

| 76x76 | 0.0095 | 0.241 | 0.0037 | 0.094 | 51.7 | 6.99 |

| 80x80 | 0.0088 | 0.224 | 0.0037 | 0.094 | 49.6 | 7.39 |

| 90x90 | 0.0076 | 0.193 | 0.0035 | 0.089 | 47.8 | 7.48 |

| 94x94 | 0.0071 | 0.18 | 0.0035 | 0.089 | 45 | 7.84 |

| 105x105 | 0.0065 | 0.165 | 0.003 | 0.076 | 46.9 | 6.41 |

| 120x120 | 0.0058 | 0.147 | 0.0025 | 0.064 | 47.3 | 5.07 |

| 165x165 | 0.0042 | 0.107 | 0.0019 | 0.048 | 47.1 | 4.04 |

| 200x200 | 0.0034 | 0.0864 | 0.0016 | 0.0406 | 46.2 | 3.48 |

| 230x230 | 0.0029 | 0.0737 | 0.0014 | 0.0356 | 46 | 3.06 |

| 400x400 | 0.0016 | 0.0415 | 0.0009 | 0.022 | 35.1 | 2.9 |

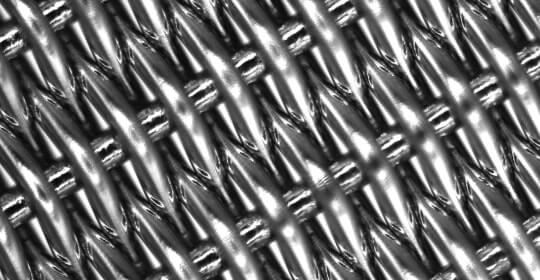

A twill pattern follows the same principle as plain weave, but each passes alternately under and over two warp wires and vice versa. As a consequence of the woven path, the strand is deformed less during weaving, which not only allows a larger diameter wire to be used, but also results in a stronger structure when compared to the plain weave counterpart. Twill weave meshes are generally woven with apertures smaller than 70 microns, 250 mesh for example, but coarser specifications can be produced when required.

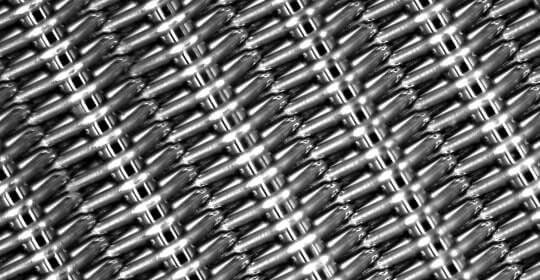

In a Plain Dutch Weave, the diameter of the warp wire is larger than the weft, and the mesh is formed by weaving a limited number of warps with the maximum number of weft wires woven tightly together, producing a cloth with no readily visible apertures. This mesh is strong and stable, easy to clean and with a good flow rate suitable for high pressure liquid/solid separation.

| Plain Dutch Weave | |||

| Mesh count per inch | Wire diameter inches | Absolute filter rating microns | Nominal filter rating microns |

|---|---|---|---|

| 8x85 | .014x.0126 | 318-340 | 250-255 |

| 12x64 | .024x.0165 | 270-285 | 200-205 |

| 14x88 | .020x.013 | 225-245 | 150-155 |

| 20x150 | .0098x.007 | 155-165 | 100-105 |

| 24x100 | 0.15x.010 | 115-125 | 80-85 |

| 30x150 | .009x.007 | 95-100 | 65-70 |

| 40x200 | .007x.0055 | 65-70 | 55-60 |

| 50x250 | .0055x.0045 | 55-60 | 40-45 |

| 80x400 | .0049x.0028 | 43-48 | 35-40 |

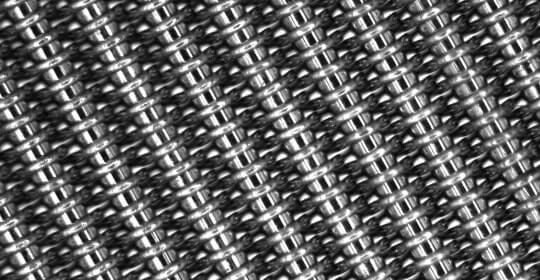

Twill Dutch Weave is produced with the weft wires packed together in the same principle as Plain Dutch Weave, but with double the number of weft wires woven in an over two, under two pattern.

The weft wires overlie each other creating a sinuous path of filtration. The cloth is very robust with a smooth surface and the finer weft wires and smaller pore sizes provide excellent flow characteristics.

The finest filtration rates are obtained with this type of weave.

| Twill Dutch Weave | |||

| Mesh count per inch | Wire diameter inches | Absolute filter rating microns | Nominal filter rating microns |

|---|---|---|---|

| 20x250 | .0098x.0079 | 110-120 | 98-105 |

| 30x360 | .0098x.0060 | 90-100 | 80-84 |

| 40x560 | .0070x.0040 | 70-75 | 47-52 |

| 80x700 | .0040x.0030 | 35-40 | 24-26 |

| 200x600 | .0024x.0018 | 28-32 | 19-21 |

| 165x800 | .0028x.0020 | 24-26 | 14-16 |

| 165x1400 | .0028x.0016 | 16-18 | 9-11- |

| 200x1400 | .0028x.0016 | 012-14 | 5-6- |

| 250x1400 | .0022x.0016 | 011-12 | 3-4- |

| 325x2300 | .0015x.0010 | 08-09- | 2-3- |

This is produced in a reverse of the Plain Dutch Weave wire arrangement, whereby finer warp wires are positioned tightly together and a thicker weft wire is woven in at set intervals. The cloth is mechanically strong with a high throughput and it performs particularly well in high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are important

| Reverse Plain Dutch Weave | ||||||||

| YKM Code | Mesh | Wrap | Weft | Nominal | Absolute | Porosity theor(%) | Weight(kg/m2) | Cloth Thickness(mm) |

|---|---|---|---|---|---|---|---|---|

| RPD 15 | 720X140-150 | 35 | 110 | 15 | 16-20 | 25 | .65-.70 | .15-.18 |

| RPD 20 | 630X125-130 | 42 | 125 | 17 | 22-26 | 53 | .75-.85 | .20-.22 |

| RPD 25 | 600X100-105 | 42 | 140 | 25 | 34-38 | 57 | .75-.80 | .22-.23 |

| RPD 40 | 280X60-70 | 90 | 200 | 40 | 54-60 | 56 | 1.34-1.55 | .38-.40 |

| RPD 60 | 175X40-50 | 150 | 300 | 60 | 65-72 | 55 | 2.1-2.40 | .57-.60 |

| RPD 80 | 130X30-35 | 200 | 380 | 80 | 95-105 | 57 | 2.7-3.10 | .77-.8 |

| RPD 85 | 175X37 | 85 | 100-106 | 54 | 2.1 | 0.57 | ||

| RPD 90 | 170X40 | 90 | 106-118 | 54 | 2.1 | 0.57 | ||

| TRD 125 | 260X40 | 125 | 112-125 | 54 | 2.25 | 0.62 | ||

| TRD 400 | 84X14 | 450-530 | 62 | 3.5 | 1.15 | |||

Manufactured as a Reverse Plain Dutch Weave in a twill pattern, which reduces the deformation of the warp wire, this cloth is very stable and particularly strong in the warp direction with a high flow rate. It is well suited to high pressure filtration including continuous filter screens used in polymer filtration and selected sand screen applications for which custom/bespoke specifications have been developed.

Typically a rectangular aperture, each warp wire passes over four wires and under one to provide a very smooth surface on one side which encourages the efficient removal of filter cake. The cloth is also exceptionally strong with high flow rates and good dewatering qualities.

Crimped Wire Mesh is made through crimping mesh machine with pre-crimped wire in the following styles listed. Square or rectangular openings available due to the different crimping styles./p>

Two-way separated wave crimping

Locked crimping

Flat-topped crimping

Two way crimping

One-way separated wave crimping

Petroleum, chemical, automotive, new energy, food, pharmaceutical and other industries.

304, 316, 304L, 316L, 310S, 430, 317L, 904L, Hastelloy, N6 , Anti high temperature materials ect

Square (plain weave,Twill weave),dutch (plain dutch weave,twill-dutch weave,double warp dutch weave,reverse plain dutch weave,reverse twill dutch weave,)

With anti-acid,anti-alkali,anti-high temperature,wear-resistant properties.